Mission critical refers to any component, equipment, personnel, process, procedure, software, etc. that is essential to operations. Types of mission critical facilities include hospitals, data centers, emergency response centers, financial institutions, military sites, utilities, and water treatment sites. Highland Tank is committed to supporting specific mission critical needs from water and fuel storage, to cooling and heating, and more.

Selected Applications

Data centers prioritize continuous uptime and minimize downtime through redundancy, backup systems, and robust infrastructure. While these facilities are built to withstand potential disruptions, Highland Tank’s products play a crucial role in maintaining operations.

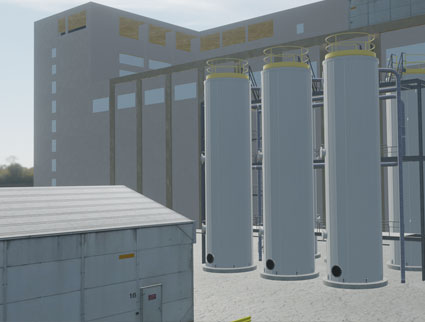

Highland Tank’s Thermal Energy Storage Tanks are engineered to delay the effects of cooling failure. Thermal Energy Storage Tanks are a great option when back-up cooling capacity is needed, load shifting is required, loads are cyclical, or an interruption in cooling cannot be tolerated by a mission critical operation.

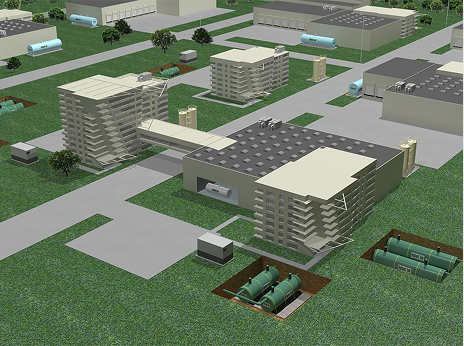

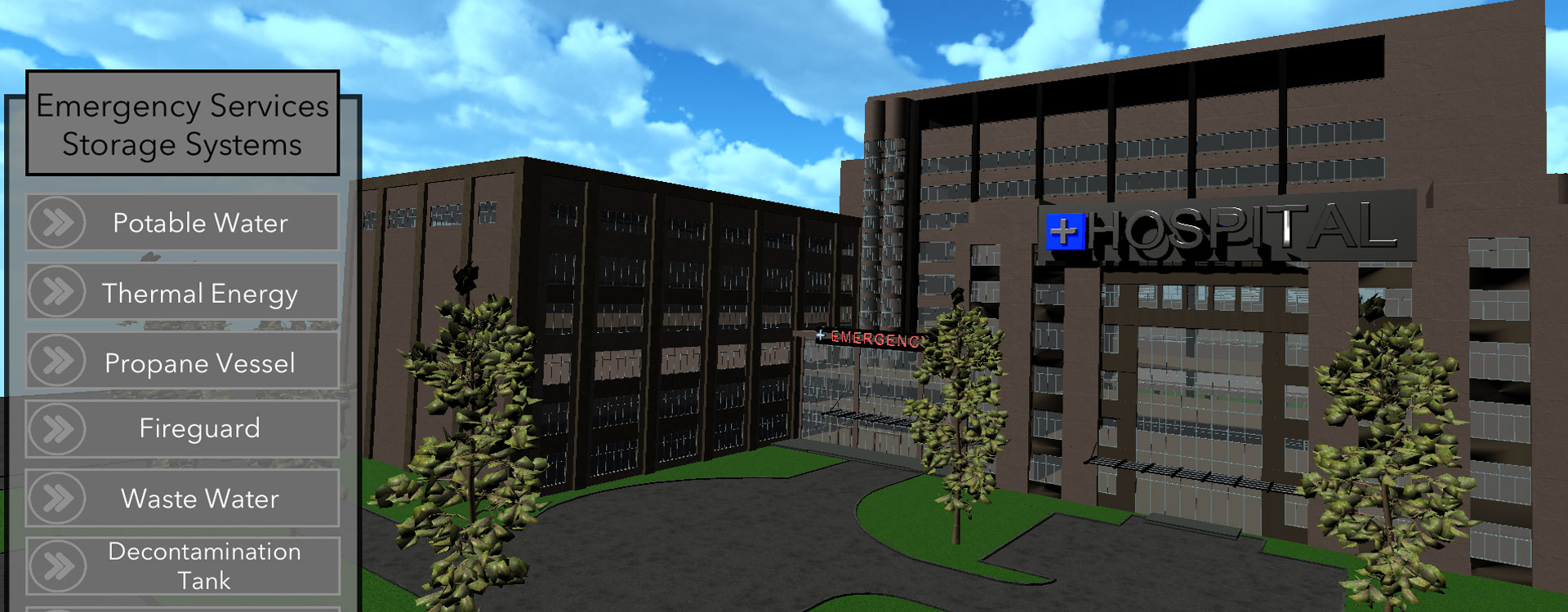

Mission critical facilities require redundancy as insurance against power outages. Highland Tank’s systems for Emergency Services can provide safe and secure storage for fuel and water supplies, ensuring that mission critical facilities can maintain operations during emergencies.

Hospitals and healthcare facilities are often required to develop effective Emergency Water Supply Plans (EWSP). This standard outlines facilities need for:

- Water for consumption and essential care activities

- Water for equipment and sanitary purposes.

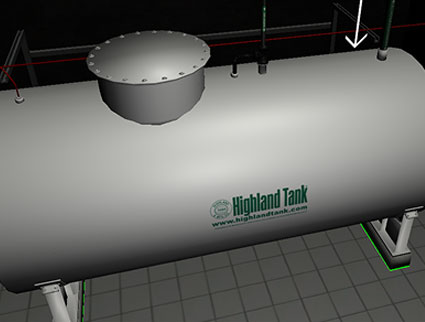

Highland Tank’s potable and non-potable water storage tanks are an effective and economical way to store water for commercial, institutional, and industrial applications. Storage tanks allow for redundant, on-site water supplies to be located where needed using atmospheric pumps and/or pass-through pressurized ASME vessels for water delivery.

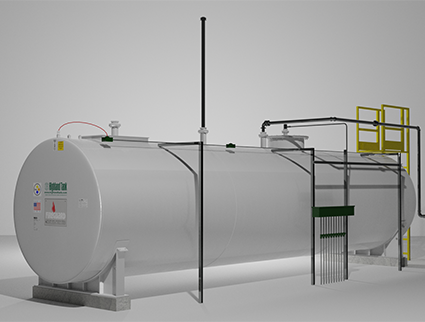

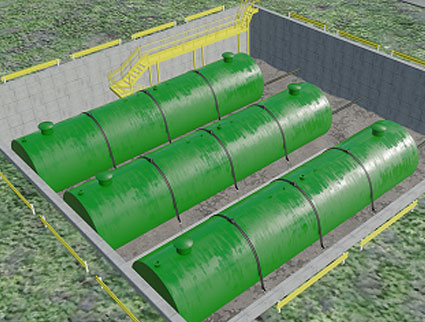

Highland Tank also offers an array of fuel storage tank options to power backup generation systems. These systems often require 72 hours worth of power from stored fuel. Our Highguard underground fuel storage tanks or the robust FIREGUARD® aboveground tanks are both reliable options for powering emergency generators.

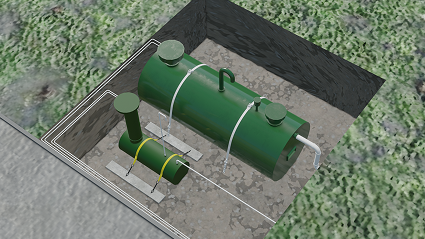

High-DRO® Wastewater storage tanks are required for use in wastewater systems where individuals or companies are responsible for disposal of their own domestic, commercial, industrial, or agricultural liquid wastes. These “tight” tanks are available for either aboveground or underground installations and are designed to store a wide range of contaminated wastewater. Wastewater storage tanks are available in single-wall or double-wall construction and in a wide range of sizes, capacities.

Carbon steel construction is standard with stainless steel available to withstand a wider range of temperatures, chemicals and pH factors encountered in industrial applications. High-solids epoxies, polyurethanes, rubber, PVC and other sheet linings, all dependent on the project and the liquid to be stored, are available for interior and exterior protection.

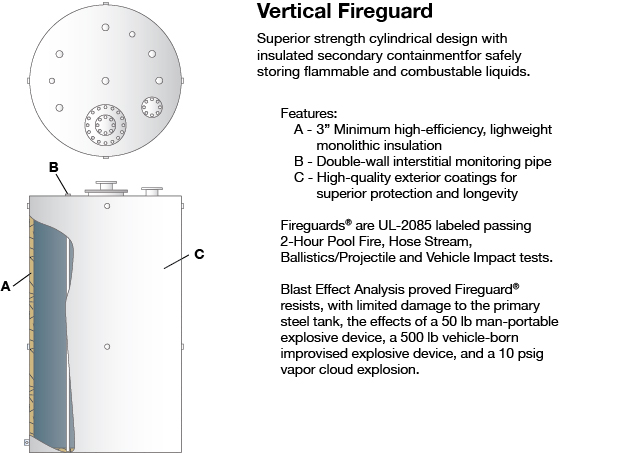

FIREGUARD® tanks are thermally protected, double-wall steel storage tanks, providing the best alternative for safe storage of motor fuels and other flammable and combustible liquids aboveground. They are used where a fire-protected tank is needed because of setback or regulatory requirements. Each tank is constructed with a minimum 3” interstice around the inner tank. The interstice is completely filled with a high efficiency insulation that protects the inner tank in the unlikely event of a fire or extreme heat. It is porous to allow fluid migration through the interstice to the monitoring point. Unlike concrete encased tanks, FIREGUARD® tanks’ steel outer wall protects the insulation, eliminating the problem of cracking and spalling concrete.

Because of its unique construction, each tank is pressure-testable in the factory and at the jobsite. With FIREGUARD®, there is no question of compliance with fire codes; the tank is shipped with factory-installed emergency vents on both the primary and the secondary containment tanks for protection if exposed to fire or excessive pressure. All FIREGUARD® tanks carry a 30-year limited warranty.

Thermal Energy Storage systems are engineered process tanks or vessels that add heat or remove heat from a storage medium such as water. These tanks are a key element in delaying the effects of cooling failure due to power loss or catastrophic failure. TES provides a low cost from of storage that can be either a pressurized ASME vessel or atmospheric UL-142 storage tank. The most common chilled water TES tank is a cylindrical, vertical pressurized water storage vessel. Environmental benefits include reduction of source energy use, decreased refrigerant charge, and improved efficiency of the energy supply.

Because Highland Tank’s TES tanks are made of steel, non-corrosive PVC diffusers, and minimal, if any VOC coatings, life cycle costs are at a minimum.

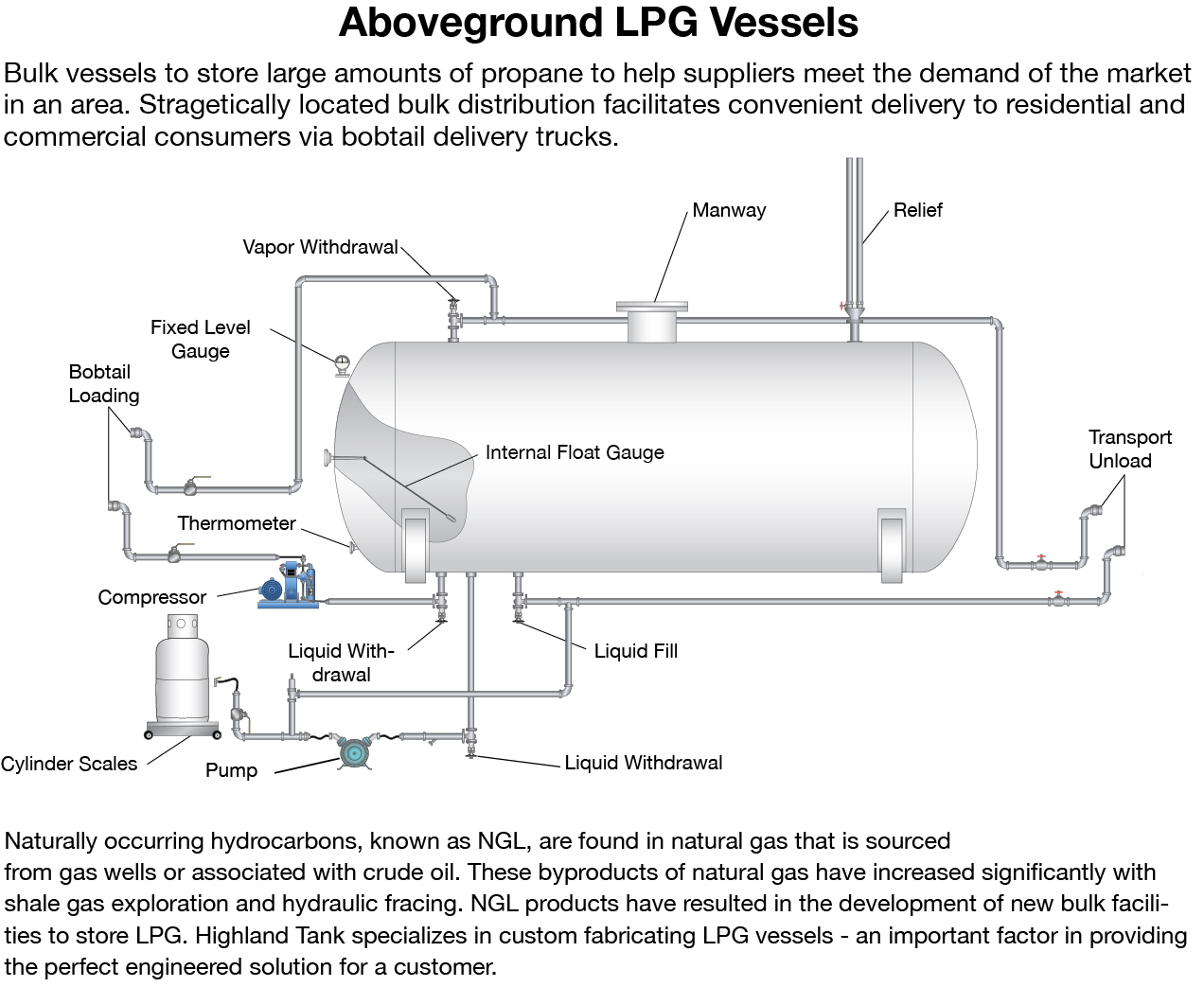

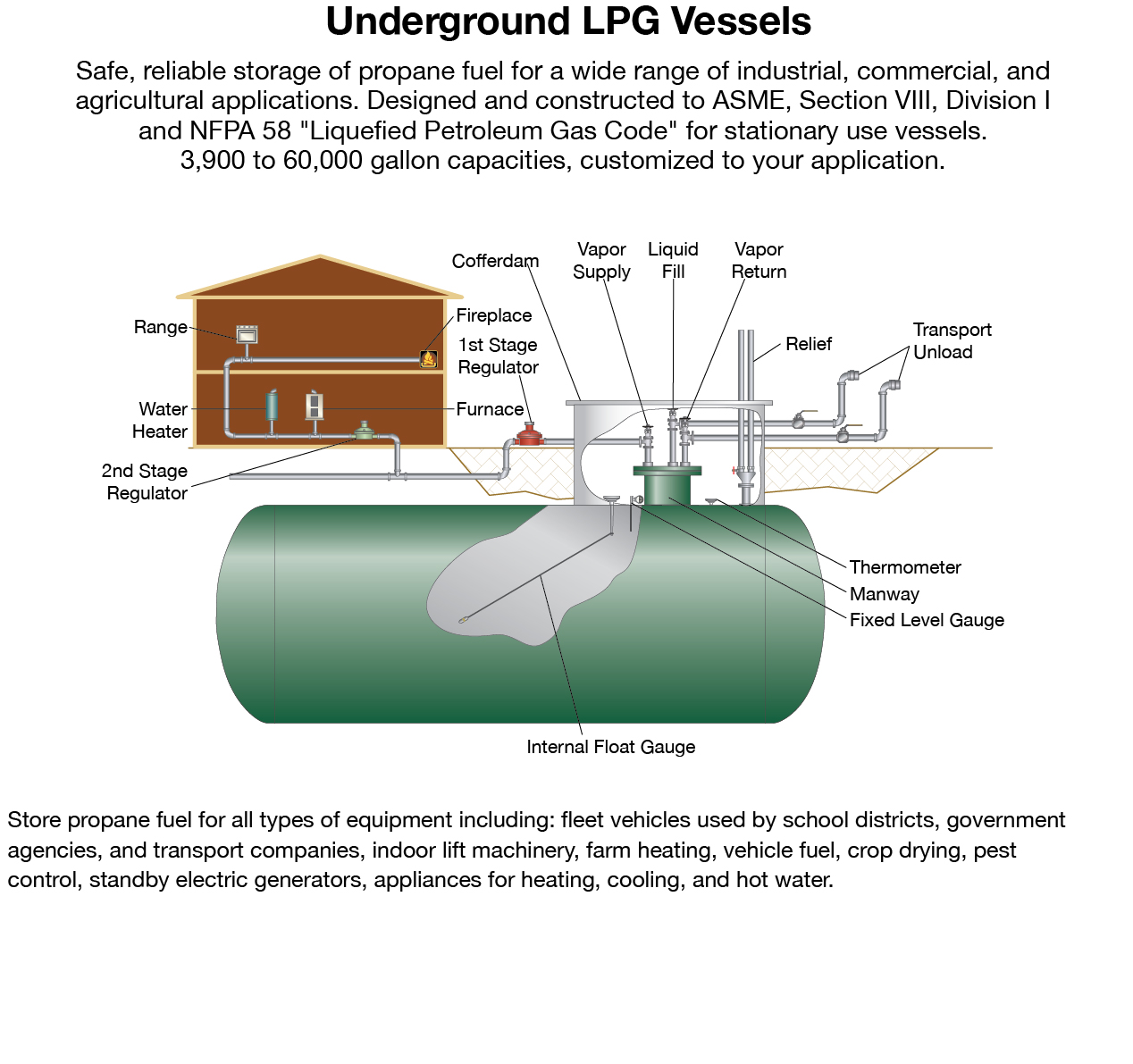

Highland Tank’s LPG vessels are designed and constructed to ASME, Section VIII, Division I and NFPA 58 “Liquefied Petroleum Gas Code” for stationary use vessels. Standard vessel sizes for industrial and commercial bulk uses range from 3,900 to 60,000 gallons.

Large LPG storage vessels provide fuel for a range of uses such as redundant fuel source for hospitals and mission critical facilities as well as standby electric generators.

High-DRO® Decontamination Wastewater Storage Tanks are required at medical facilities to hold or store wastewater generated as a result of decontamination activities performed to remove chemical, biological, radiological, and nuclear (CBRN) residue or hazardous materials (HazMat) from equipment or personnel. These “tight” tanks are available for either underground or aboveground installations and are designed to store a wide range of contaminated wastewater.

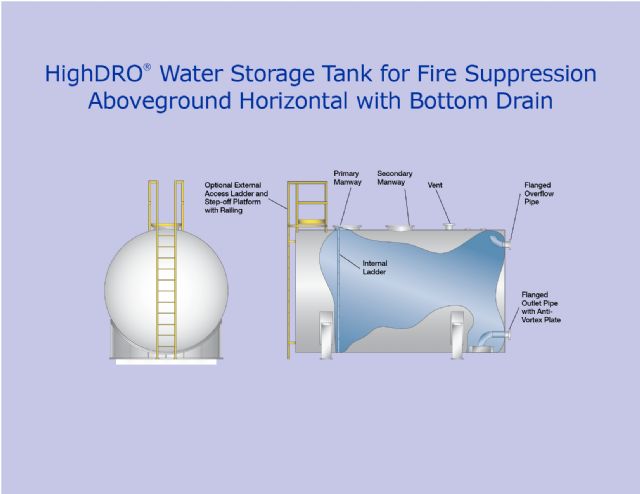

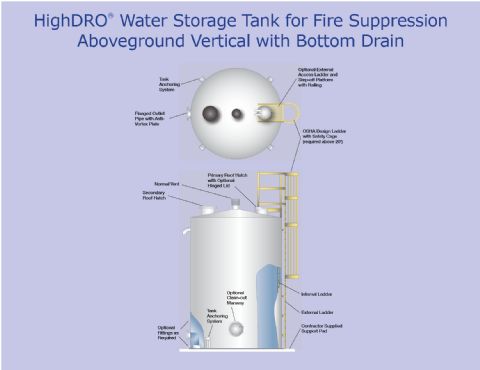

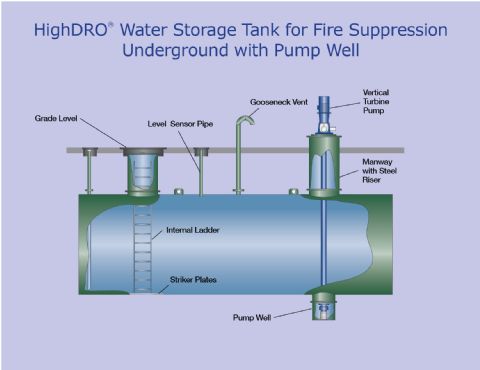

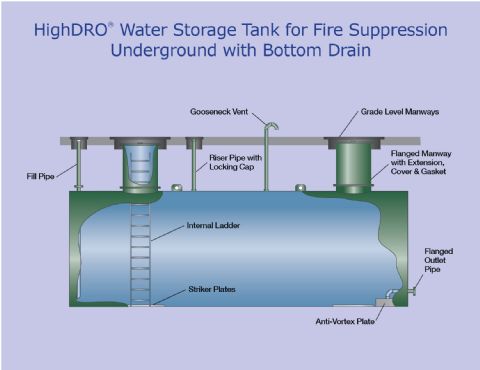

Fire protection tanks are hydropneumatic water storage tanks designed for use in fire protection systems. These tanks are required by fire codes in many commercial, industrial, and institutional buildings for use with automatic sprinkler systems for fire suppression. Fire protection vessels are designed, fabricated, tested, inspected, and installed in accordance with the National Fire Protection Association NFPA Standard No. 22, “Water Tanks for Private Fire Protection.” Building and fire codes may require a secondary on-site water supply for high-rise buildings. Compliance may result in a secondary water supply equal to the hydraulically calculated sprinkler and hose stream design demand with a required duration time up to 30 minutes.

High-DRO® Decontamination Wastewater Storage Tanks are required at medical facilities to hold or store wastewater generated as a result of decontamination activities performed to remove chemical, biological, radiological, and nuclear (CBRN) residue or hazardous materials (HazMat) from equipment or personnel. These “tight” tanks are available for either underground or aboveground installations and are designed to store a wide range of contaminated wastewater.

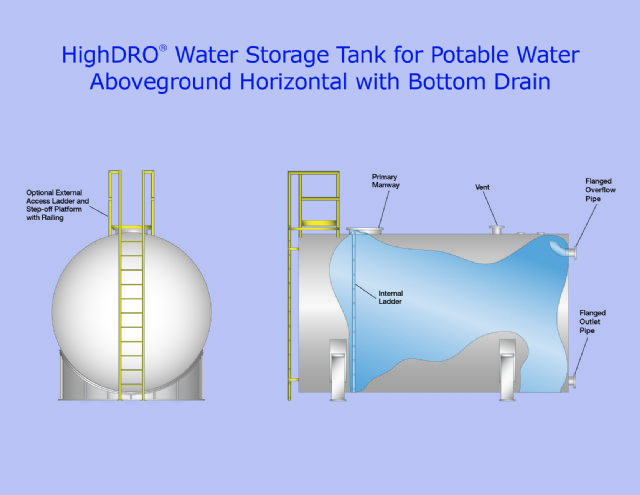

High-DRO® Potable water tanks are an effective and economical way to store potable water for residential, commercial, institutional and industrial installations. These factory-welded and coated carbon steel water tanks are pressure tested for tightness to ensure the quality and dependability of the water supply. The high-strength steel shell combines with our High-DRO® Liner Plus polymer composite interior liner to provide a flexible, long lasting tank system. Potable water tanks are constructed to the highest standards to ensure a safe, contamination free environment.

Our interior liner complies with NSF/ANSI 61 Drinking Water System Components – Health Effects for the safe storage of potable water. Our exterior corrosion protection systems for underground water tanks comply with UL-1746. Aboveground tanks can be protected with a wide selection of primers and topcoats, even those complying with ANSI/AWWA D102-03, “Coating Steel Water-Storage Tanks”.

Aboveground Horizontal Bottom Drain

Aboveground Vertical Bottom Drain

Underground With Pump Out

Underground Bottom Drain

Aboveground Horizontal Bottom Drain