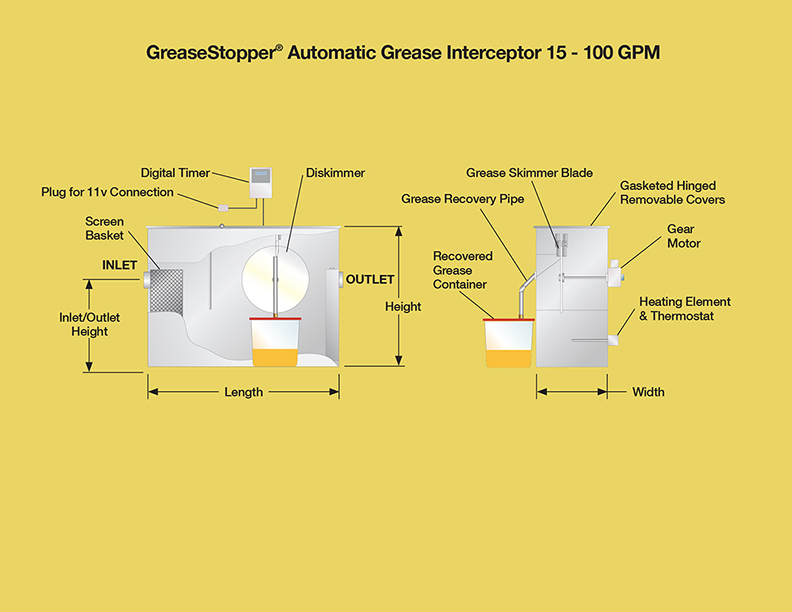

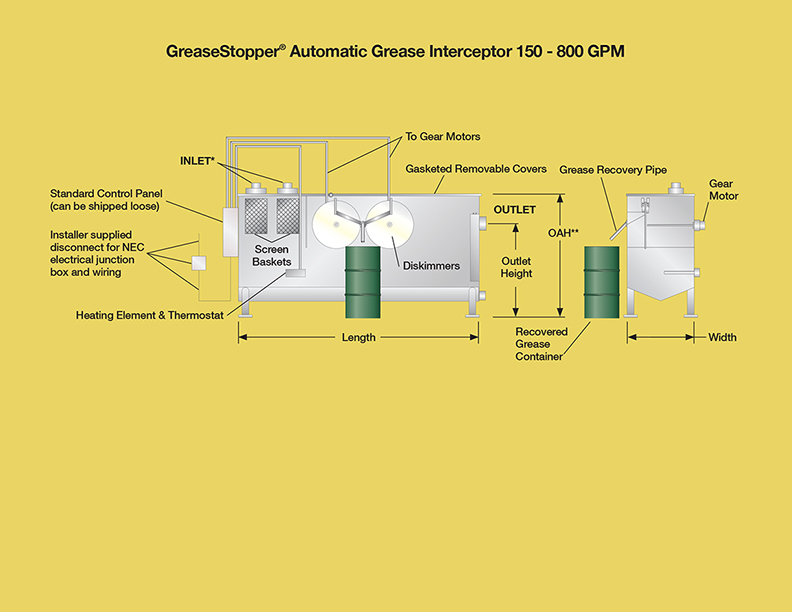

GreaseStopper® Automatic Grease Interceptors intercept and remove large quantities of FOG discharged from food service facilities and large commercial/institutional kitchens. They are suitable for aboveground or vaulted underground installations. They range in capacity from 15 to 800 GPM and incorporate and electrically powered grease-skimming device to remove accumulated FOG on a timed or event basis.

The High-LINK® Integrated Systems couples Highland Tank’s superior steel tank products with state-of-the-art electronic management devices and proprietary software to provide real-time data to decision-makers. With our High-LINK® applications you will have the power to optimize the usage and transfer of all your liquid operations. Learn more here.

15-100 GPM GreaseStoppers® are designed for installation under a sink or other limited space. The skimmed grease is collected in a waste disposal container for disposal or recycling.

GreaseStopper® Automatic Grease Interceptors are designed to intercept and remove large quantities of fats, oils, and grease (FOG) discharged from food service facilities and large commercial/institutional kitchens. They are suitable for aboveground or vaulted underground installations. The larger volume, end-of-pipe AGI units are usually installed in the building’s basement and service an entire facility’s kitchen fixtures, including all floor drains.

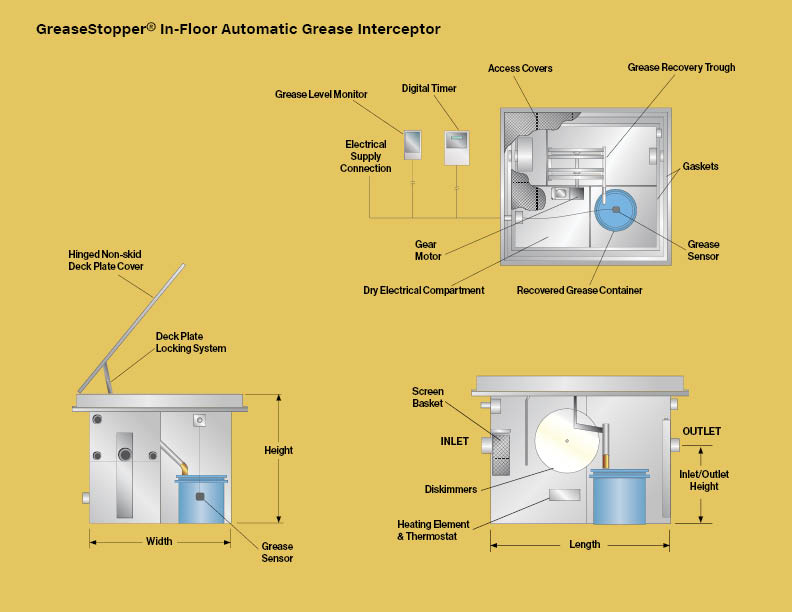

The In-Floor GreaseStopper® is recessed with its top flush with the floor in order to intercept kitchen fixtures and floor drains, save valuable above floor space and accommodate existing piping and structural conditions. This specialized grease removal device features an integral Automatic Grease Interceptor with separate grease storage and dry electrical compartments. It is equipped with a hinge cover that opens to reveal the entire unit for easy maintenance.

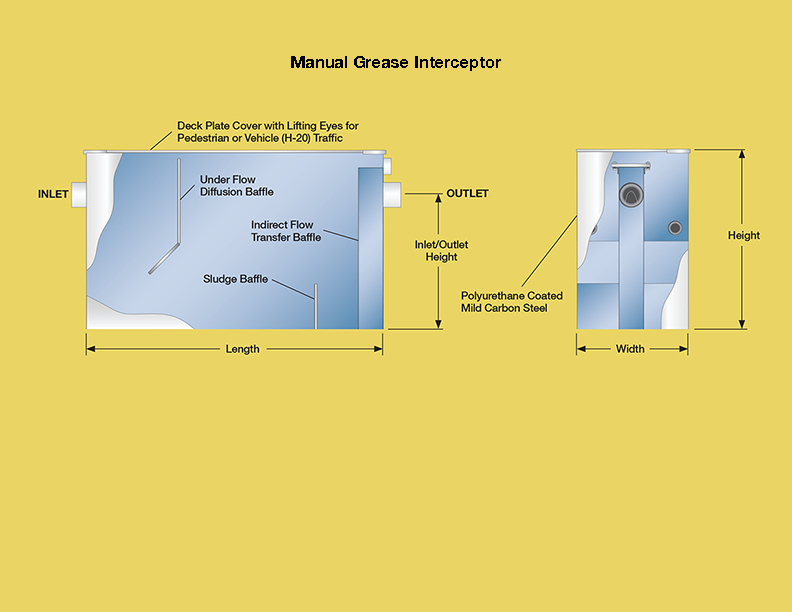

Manual Grease Interceptors are installed where they can be hooked up to a sanitary sewer that does not mandate an automatic grease recovery unit. The operation of the MGI is simple. Manual Grease Interceptors retain wastewater long enough to allow those contaminants with specific gravity different than water, to separate out by gravity flotation and settling.

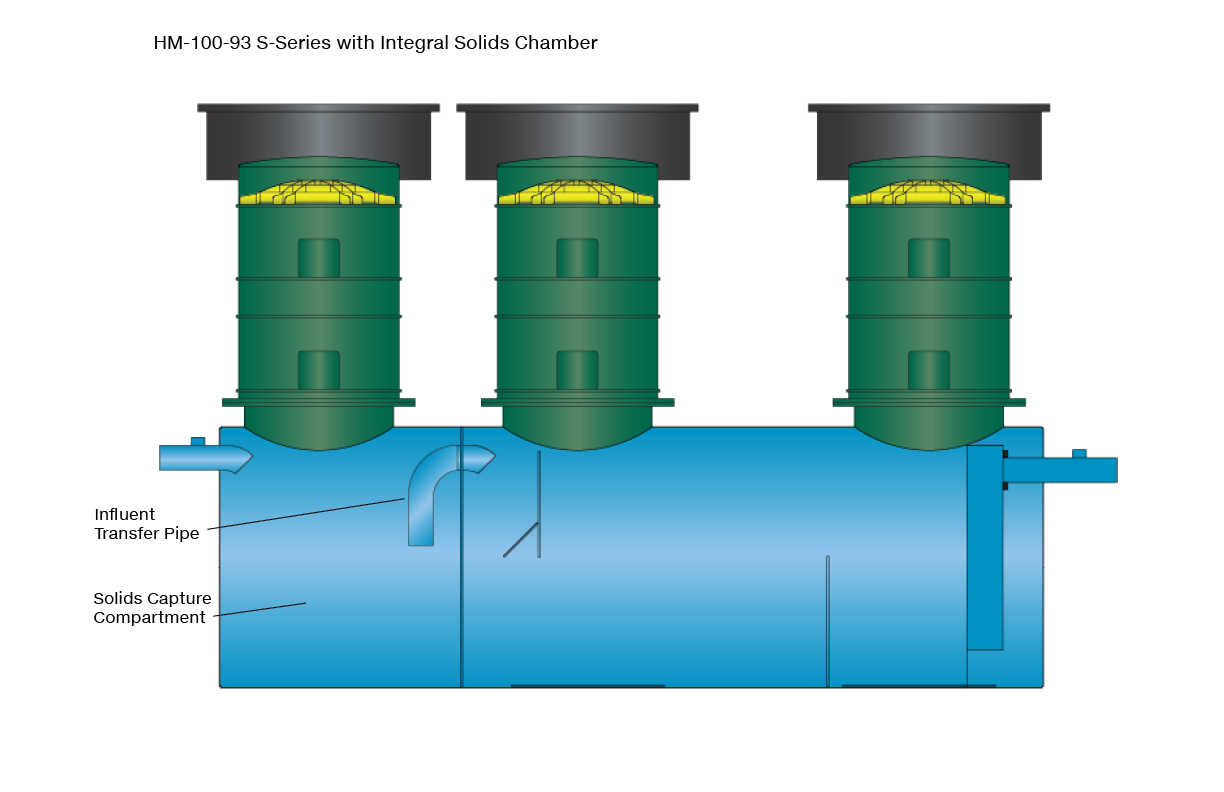

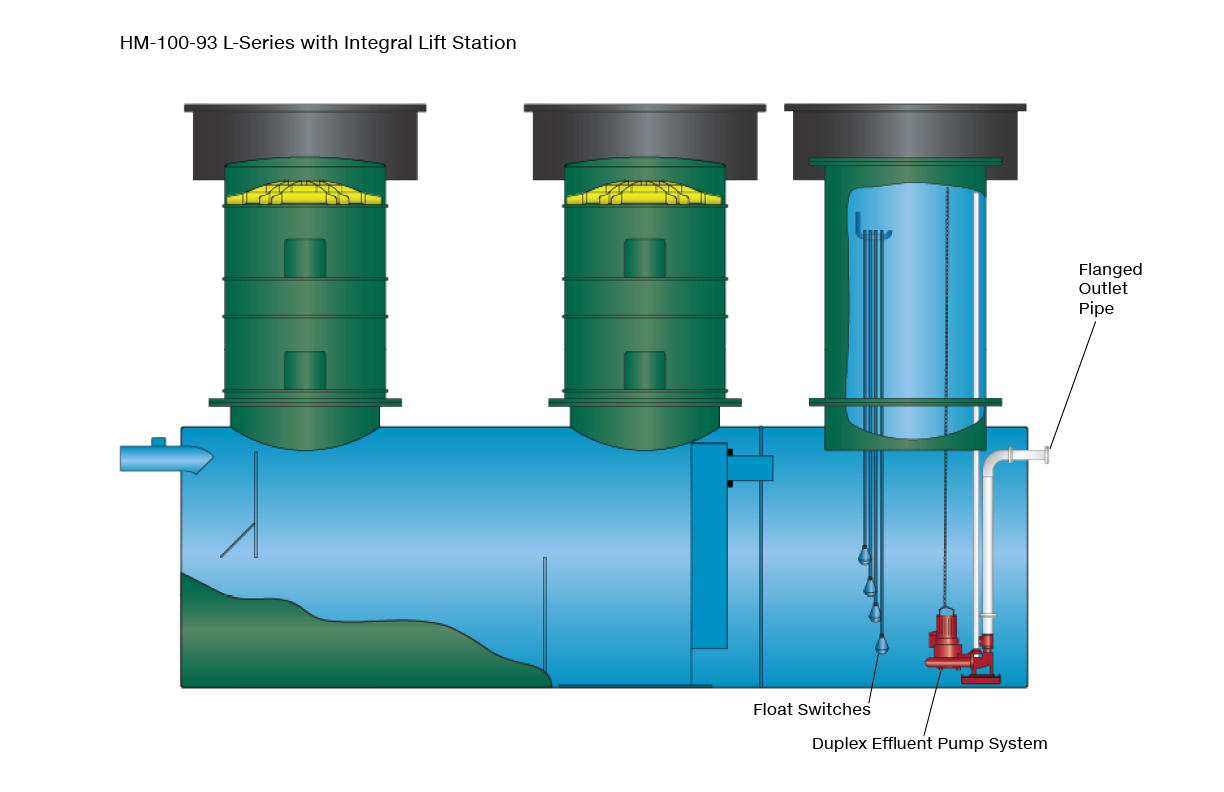

Highland Tank is proud to introduce our 100 GPM hydro-mechanical grease interceptor, the HM-100-93. These grease interceptors are designed to trap and collect large quantities of sewer-clogging fats, oils, grease, and solids (FOGS) commonly discharged from commercial kitchens. The HM-100-93serves as a central grease interceptor in lieu of multiple smaller units, typically installed at fixtures. Installed above or below ground outdoors, they are typically connected to sanitary sewer systems as an alternative to larger gravity (passive) grease interceptors.

The HM-100-93 was recently tested at NSF Laboratories to the first performance test standard —PDI-G101 for hydro-mechanical grease interceptors. The results proved its performance superior to similar products tested to date. Miami-Dade County in Florida was the driving force behind this testing since they require 99% efficiency for all hydro-mechanical grease interceptors. We are pleased to add the HM-100-93 grease interceptor to our existing grease removal systems product line. We encourage you to contact PDI or request copies of test reports by certified laboratories to validate grease interceptor performance

Automatic Grease Interceptor Training Video

GreaseStopper In Floor